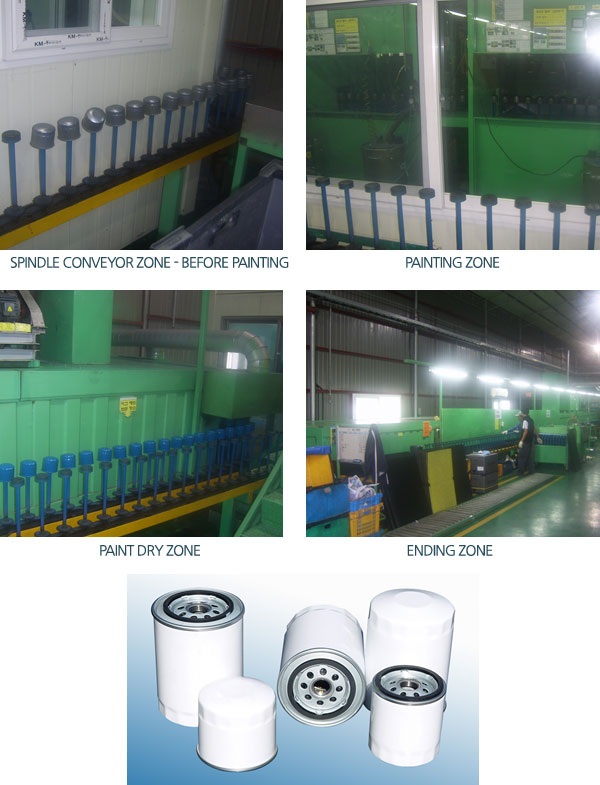

Housing Paint Line(Model : UHP-50A, Powder Type)

- PRODUCTION CAPACITY : 15/ 30/ 50 pcs/ min

- AVAILABLE HOUSING HEIGHT : 65~310mm

- AVAILABLE HOUSING DIA :

60~

60~ 135

135 - FIVE TANK TYPE

A) PRE-DEGREASING(WATER) : 35

5

5 (1~2 min)

B) DEGREASING : 55

(1~2 min)

B) DEGREASING : 55 5

5 (2~3 min)

C) RINSING(WASHING) : 35

(2~3 min)

C) RINSING(WASHING) : 35 5

5 (1~2 min)

D) PHOSPHATE : 50

(1~2 min)

D) PHOSPHATE : 50 5

5 (2~3 min)

E) RINSING(WASHING) : 50

(2~3 min)

E) RINSING(WASHING) : 50 5

5 (1~2 min)

F) DRY(140~160

(1~2 min)

F) DRY(140~160 x 5min)

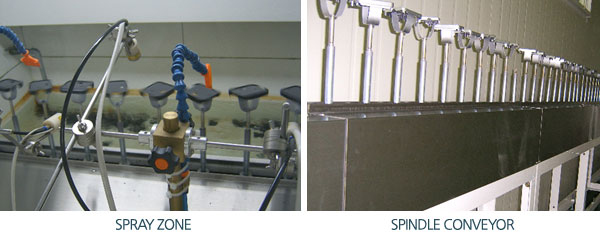

x 5min) - CONVEYOR TURNING SPEED(ON PAINT SPRAY PROCESS : 3m~ 5m/min

- INFRARED RAYS HEATING SYSTEM & AUTOMATIC TEMP. CONTROL TYPE

- INDIVIDUAL OPERATION CONTROL PANNEL

- 3 WAY TURNEL & 5 WTATER TANK TYPE

- PAINT THICKNESS : 10~13

- AUTOMATIC CONVEYOR SPEED CONTROLLER INSTALLED

- OVER TEMP. PROTECTOR CONTROL/ SAFTY DEVICE INSTALLED

- EMERGENCY STOP SYSTEM INSTALLED

- REFLECTOR : WATER DISPOSAL SYSTEM INSTALLED

- PAINT VISCOSITY(MIXED THINNER) : FORD CUP NO 4. 10~13 sec

- THINNER TYPE : ELECTROSTATIC THINNER

- PAINT TYPE : ELECTROSTATIC PAINT

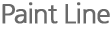

- SPARY GUN TYPE : ELECTROSTATIC GUN

- STAINLESS STEEL TOP PLATE CONVEYOR & STAINLESS WIRE NET CONVEYOR OR HANGER TYPE CONVEYOR INSTALLED

- REQUIRED PAINT LINE EQUIPMENT(REFER TO THE DETAILED LAYOUT) : PRE TREATMENT(MESH CONVEYOR, 10.5m) x DRY OVEN(12.1m) x POWDER BOOTH(1.2m FOR 1 BOOTH) x COOLING SYSTEM(2.1m) x BAKING OVEN(18m) x DUST COLLECTOR x POWEDER COATING M/C x SPINDLE CONVEYOR(164m)

TECHNICAL DESCRIPTION

- ELECTROSTATIC THINNER

- ELECTROSTATIC PAINT

- ELECTROSTATIC PAINT GUN

- ELECTRICSTAIC CONTROL SYSTEM

- CHAIN

- SPARY TIP

- PAINT FILTER

OPTIONAL PART

- THE ABOVE PHOTO IS BASE ON SPINDLE TYPE.

REMARK