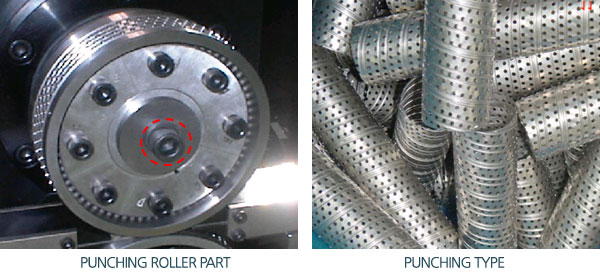

Auto Spiral Tube Making M/C(Model : UST-90E, Punching Hole Type)

- UST-90P is designed for automotive filter inside tube

- production and full automatic processing mechanism.

- punching, feeding, bending , seaming and cutting.

- High technology adapted for increase the high product

- capacity and final perfect goods.

GENERAL DESCRIPTION

- Special designed drum type punching roller

- Identify moving designed Feedidng roller with Punching roller device for prevent trouble.

- Initial material loss are zero "0"

- Feeding guide roller can be adjustable to easy settitng.

- Punch Roller's individual pin can be changeable.

- Emergency stop & Cycle stop device.

- Digital counter device.

- Turning type special cutting device to removing sharp edge and burr

- Automatic three step speed control system for reduce the punching roller burden

- Autostop system for material change

- Guarantee the accuracy within 0.5mm with high productivity.

FEATURE

- production capacity : 80~100 pcs/min

- available tube Out-Dia :

30~

30~ 70

70 - available tube length : 35mm~500mm

- cutter speed : 500 rpm

- cutting style : cutter turnning type

- Jig (model) change time : 20~25 min

- Punching Hole Size : OD4.0mm

- Raw material : width : 38mm or 42 mm(+0/-0.05) or other size tin plate steel

- thickness : 0.25~0.32mm

- Machine size : main machine(1520 x 1310 x 1220) & punching system(1390 x 675 x 1200)& Uncoiler(W850 x L1000 x H1260)

- Machine weight : 2,000 Kg

- Available Coil Specification : Coil ID : 300mm & Coil OD : Max. 900mm

SPECIFICATION

- Tube Dia change tool

- Tin Plate Steel

OPTION